- Electrical Training

- Safety

- Electrical Compliance

- Electrical Automation

- Electrical Maintenance

- Mechanical Training

- HVAC

- Codes and Standards

- Fluid Power

- Maintenance

- View All Training Programs

-

View All Electrical Safety Training ProgramsTop Electrical Safety Training Programs

- Arc Flash Electrical Safety [Based on NFPA 70E®]

- Electrical Safety: NFPA 70E Retraining

- Electrical Safety Awareness

- Electrical Safety Practical Skills for Switchgear

- Electrical Safety: Power Generation, Transmission & Distribution [based on OSHA 1910.269]

- Seguridad Eléctrica en el centro de trabajo, [Basado en el manual NFPA 70E® 2021]

Upcoming Training Programs- 05/20 - 05/21 : Virginia Beach , VA Arc Flash Electrical Safety [Based on NFPA 70E®]

- 06/03 - 06/04 : Live Online Training , CO Arc Flash Electrical Safety [Based on NFPA 70E®]

- 06/03 - 06/04 : Baltimore , MD Arc Flash Electrical Safety [Based on NFPA 70E®]

- 06/07 - 06/07 : Live Online Training , CO Electrical Safety: NFPA 70E Overview - NEW!

- 06/10 - 06/11 : Philadelphia , PA Arc Flash Electrical Safety [Based on NFPA 70E®]

-

View All Electrical Electrical Compliance Training ProgramsTop Electrical Electrical Compliance Training Programs

- 2020 NFPA 70® – National Electrical Code® [NEC]

- 2023 NFPA 70® – NATIONAL ELECTRICAL CODE® [NEC]

- Electrical Systems: SOARS Grounding & Bonding

- Electrical Systems: Hazardous Locations

- NEC® – Analysis of Changes 2020 with Practical Exercises

- NFPA 110® – Emergency & Standby Power Systems

- NFPA 70B® Standard Overview

- NFPA 70B® – Standard For Electrical Equipment Maintenance®

- NFPA 72: National Fire Alarm & Signaling Code®

- 2021 NFPA 79® – Electrical Standard For Industrial Machinery®

- NICET I & II

- National Electrical Safety Code® [NESC]

- NEC® – Analysis of Changes 2023

Upcoming Training Programs- 05/22 - 05/24 : Virginia Beach , VA 2023 NFPA 70® – NATIONAL ELECTRICAL CODE® [NEC]

- 05/22 - 05/23 : Live Online Training , CO NICET I & II

- 05/22 - 05/23 : Live Online Training , CO NEC® – Analysis of Changes 2023

- 06/05 - 06/07 : Baltimore , MD 2023 NFPA 70® – NATIONAL ELECTRICAL CODE® [NEC]

- 06/05 - 06/07 : Live Online Training , CO 2023 NFPA 70® – NATIONAL ELECTRICAL CODE® [NEC]

-

View All Electrical Electrical Automation Training ProgramsTop Electrical Electrical Automation Training Programs

- Instrumentation & Process Control

- PLCs [Programmable Logic Controllers]: Automation Systems

- PLCs [Programmable Logic Controllers]: ControlLogix & RSLogix 5000

- PLCs [Programmable Logic Controllers]: Fundamentals

- PLCs [Programmable Logic Controllers]: Siemens Simatic S7

- Tuning DDC/Process Control Loops

- Variable Frequency Drives [VFD]

Upcoming Training Programs- 05/21 - 05/23 : Centennial , CO Variable Frequency Drives [VFD]

- 05/29 - 05/31 : Centennial , CO Instrumentation & Process Control

- 06/03 - 06/05 : Phoenix , AZ PLCs [Programmable Logic Controllers]: Fundamentals

- 06/04 - 06/06 : Reno , NV Variable Frequency Drives [VFD]

- 06/06 - 06/07 : Phoenix , AZ PLCs [Programmable Logic Controllers]: Automation Systems

-

View All Electrical Electrical Maintenance Training ProgramsUpcoming Training Programs

- 05/29 - 05/31 : Elk Grove , IL Fiber Optics

- 06/04 - 06/05 : Houston , TX Basics of Industrial Electricity

- 06/05 - 06/06 : Centennial , CO Electrical Print Reading: Blueprints & Schematics

- 06/06 - 06/07 : Houston , TX Electrical Motor Control Circuits: Troubleshooting

- 06/07 - 06/07 : Live Online Training , CO Electrical Safety: NFPA 70E Retraining

-

View All Mechanical HVAC Training ProgramsTop Mechanical HVAC Training Programs

- Balancing of Water and Air Systems

- Boilers: An Operational Workshop

- HVAC: Brazing [Advanced]

- Air Conditioning & Refrigeration: Advanced

- HVAC: Air Conditioning & Refrigeration

- HVAC: Principles of Heating & Ventilation

- Chillers: Operation & Maintenance of Chilled Water Systems

- Steam Distribution Systems

- Water Treatment for Boilers and Chilled Water Systems

Upcoming Training Programs- 05/21 - 05/23 : Las Vegas , NV HVAC: Air Conditioning & Refrigeration

- 05/21 - 05/23 : Centennial , CO Boilers: An Operational Workshop

- 05/21 - 05/23 : Sacramento , CA Chillers: Operation & Maintenance of Chilled Water Systems

- 06/04 - 06/06 : Saint Louis , MO HVAC: Air Conditioning & Refrigeration

- 06/11 - 06/13 : Reno , NV HVAC: Air Conditioning & Refrigeration

- View All Mechanical Codes and Standards Training Programs

-

View All Mechanical Fluid Power Training ProgramsUpcoming Training Programs

- 05/28 - 05/31 : Centennial , CO Hydraulics & System Troubleshooting

- 06/11 - 06/14 : Centennial , CO Hydraulics & System Troubleshooting

- 06/25 - 06/27 : Centennial , CO Centrifugal Pumps

- 07/23 - 07/26 : Houston , TX Hydraulics & System Troubleshooting

- 08/13 - 08/16 : Phoenix , AZ Hydraulics & System Troubleshooting

-

View All Mechanical Maintenance Training ProgramsUpcoming Training Programs

- 06/11 - 06/13 : Centennial , CO Mechanical Drives & Power Transmission

- 07/30 - 07/31 : Centennial , CO Electric Motors: Understanding & Troubleshooting

- 08/06 - 08/07 : Centennial , CO Principles of Bearings & Lubrication

- 08/08 - 08/09 : Centennial , CO Shaft Alignment with Laser Technology

- 09/17 - 09/19 : Centennial , CO Mechanical Drives & Power Transmission

Select the following link if you would like to recover a report that has been previously deleted.

NTT Blog

05/01/2019

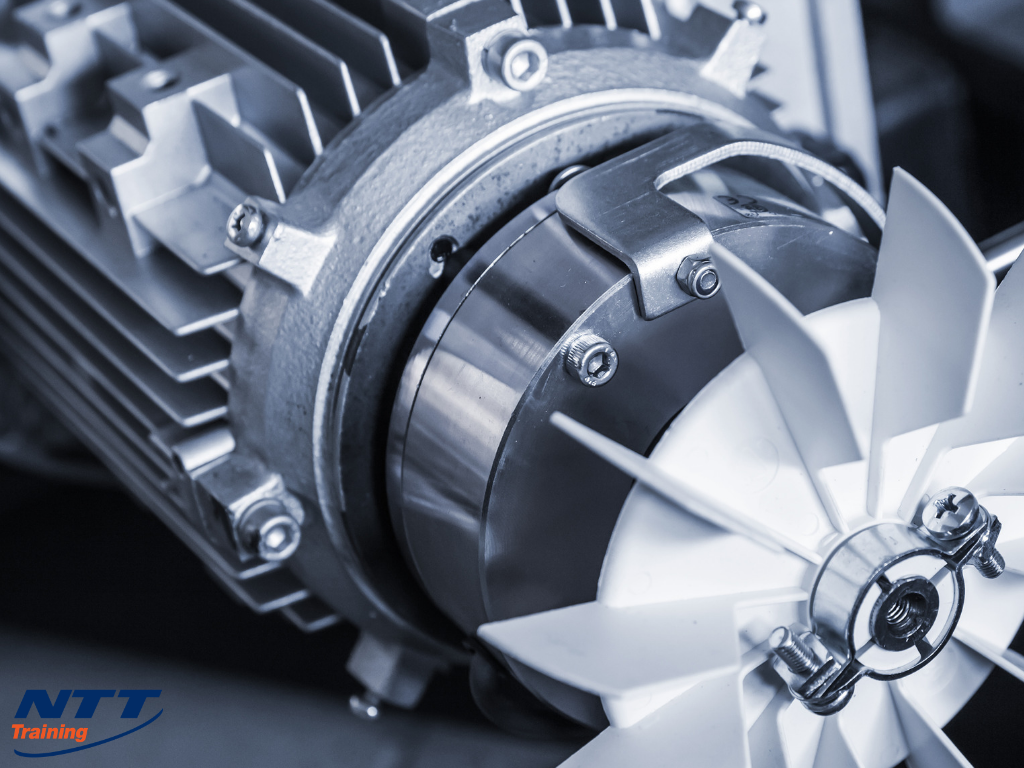

Mechanical Drives and Troubleshooting Issues that May Arise

Mechanical drive systems are an important of many industrial operations. Repairing and maintaining these complex machines requires a high level of knowledge and skill. Employers in the marine, nuclear, and other industries that require automated moving systems benefit from having a maintenance staff that is trained to handle mechanical drives and transmissions.

What are mechanical drives? What are some common troubleshooting issues that occur with these machines? Why is it important for employees to train their staff in basic troubleshooting techniques?

What is a Mechanical Drive?

Mechanical drives are a series of components that manages the transmission. This power can be channeled to power other equipment like pumps, blowers, air compressors, and other common industrial machinery. They can also be found in some older passenger vehicles and motorized equipment like forklifts and electric pallet jacks. These vital mechanisms make it easier and safer to perform a range of industrial duties.

Like any other piece of machinery, mechanical drives can suffer damage or breakdowns that compromise their ability to work correctly. In these cases, industrial operations can find their production lines shut down while they wait for repairs.

These are some of the most common problems experienced with mechanical drives.

- Lack of speed. Equipment may mysteriously slow down, lose suction, or simply not hold up to historical performance standards.

- Not stopping or starting. Drives may freeze up and not respond to startup procedures or won’t stop working until the power supply is disconnected.

- Overheating. The equipment may still function properly. However, excessive heat escapes the equipment and causes damage to surrounding mechanisms.

- Erratic fuel consumption. Compromised motors may use too much fuel to handle the same demands.

- Inconsistent current regulation. The mechanical drive may not be able to provide enough usable current to power the equipment to which it is attached.

These problems happen often and are usually due to regular wear-and-tear. However, it is important to address these issues as soon as possible to ensure your operations can continue normally.

How Training Employees to Troubleshoot Mechanical Drives Benefits Employers

Without your machinery, your business can’t function. Having employees on-staff who are trained in troubleshooting mechanical drives helps businesses operate efficiently in a variety of ways.

- Mechanical drives are usually part of a complex network of machines and accessories. It takes a high level of specialized knowledge to service these devices. Depending on the area and industry that your business is in, it could be difficult to find a repairperson on short notice. When they finally arrive, the problem could be something simple and easy to fix. In that situation, you waste valuable time and money. Having trained staff members mean you won’t have to invest large amounts of resources into small problems.

- In some cases, shady mechanics may take advantage of your staff’s lack of knowledge. They may inflate the severity of your mechanical drive’s issues in an effort to charge more for repairs and maintenance. With a trained staff, you won’t have to worry about dishonest mechanics trying to pad your final bill.

- Maintenance is the key to keeping problems with your mechanical drive at bay. You could contract with an outside service to periodically monitor the condition of your equipment. However, this can quickly add up to a large expense. Instead, train your employees to do those duties themselves and reduce the pressure on your operational costs.

- In some industries, confidentiality is key. Letting in outside vendors and contractors could expose proprietary information. With a trained staff, you won’t have to worry about long vetting processes or potential issues with compromised privacy.

Training your staff in basic troubleshooting procedures for mechanical drives saves you time, money, and frustration.

The Mechanical Drives and Power Transmission seminar from NTT Training is the perfect way to get your team ready to take on troubleshooting duties. This 3-day, hands-on training is designed for anyone who regularly works with mechanical drives for power transmission. Students learn the different parts of a mechanical drive and how to diagnose common problems that occur with them.

Secure your industrial operation with this specialized training program. Contact our staff to schedule a training session for your employees.

Recent Blog Posts

- Confined Space Entry: How to Ensure Safe and Successful Operations

- How To Start a PM Program

- Confined Space Programs

- Are You Using PPE the Right Way?

- Why company-wide buy-in is critical to a successful CMMS program and movement to a better preventative maintenance schedule.

- Categories

- Uncategorized (18)

- Electrical Training Programs (93)

- Code & Standards (28)

- Electrical Maintenance (17)

- Mechanical HVAC (8)

- Safety (39)

- Mechanical Training Programs (74)

- Code & Standards (10)

- Electrical Safety (8)

- HVAC (17)

- Maintenance (19)

- Fluid Power (19)

- News (13)

- Onsite Training (2)

- Contractor Management (1)

- National Electric Code (5)

- OSHA Rules and Requirements (18)

- General Safety Tips (3)

- Industrial Safety (4)

- Plumbing Standards (2)

- Electrical Blueprint Reading (6)

- Natural Gas Safety (3)

- Ultrasonic Testing (1)

- PLC (10)

- High Voltage (3)

- Oil Analysis (2)

- Centrifugal Pumps (4)

- Variable Frequency Drives (6)

- Welding Safety (7)

- Chillers (3)

- Hazardous Locations (5)

- Confined Spaces (6)

- Infrared Thermography (2)

- NFPA 72 (4)

- Process Control Loops (3)

- Backflow Prevention (1)

- Electrical Grounding (2)

- Industrial Circuits (2)

- Boilers (5)

- Shaft Alignment (3)

- Hoisting and Rigging (3)

- Fiber Optics (5)

- Refrigeration (1)

- Arc Flash (8)

- NFPA 110 (1)

- Conveyor Systems (1)

- NFPA 70E (2)

- Process Instruments (1)

- Vibration Analysis (1)

- Industrial Generators (1)

- Life Safety Code (1)

- Electrical Switchgear (1)

- NFPA 79 (1)

- Steam Distribution Systems (1)

- Preventative Maintenance (1)

Filter Blogs

- August 2023 (1)

- July 2023 (1)

- June 2023 (1)

- April 2023 (1)

- March 2023 (1)

- February 2023 (1)

- December 2022 (1)

- October 2022 (1)

- August 2022 (1)

- July 2022 (1)

- October 2019 (9)

- September 2019 (8)

- August 2019 (9)

- July 2019 (8)

- June 2019 (8)

- May 2019 (9)

- April 2019 (9)

- March 2019 (7)

- February 2019 (4)

- January 2019 (9)

- December 2018 (7)

- November 2018 (7)

- October 2018 (9)

- September 2018 (6)

- August 2018 (7)

- July 2018 (9)

- June 2018 (8)

- May 2018 (9)

- April 2018 (9)

- March 2018 (8)

- February 2018 (8)

- January 2018 (9)

- December 2017 (9)

- November 2017 (8)

- October 2017 (9)

- September 2017 (8)

- August 2017 (7)

- July 2017 (5)

- June 2017 (7)

- May 2017 (8)

- April 2017 (3)

- March 2017 (7)

- February 2017 (3)

- January 2017 (4)

- December 2016 (7)

- November 2016 (4)

- October 2016 (7)

- September 2016 (5)

- August 2016 (6)

- June 2016 (1)

- May 2016 (2)

- April 2016 (2)

- March 2016 (1)

- January 2016 (2)

- October 2015 (1)

- August 2015 (1)

- July 2015 (3)

- May 2015 (1)

- March 2015 (1)

- January 2015 (3)

- April 2014 (4)

Our Mission:

"Deliver solutions to our clients (and their global workforce) designed for safety, productivity and profitability.”

NTT Training Inc. has been accredited by the Accrediting Council for Continuing Education & Training (ACCET). ACCET accreditation serves the interests of companies, agencies, and the public through the establishment of standards, policies, and procedures in conjunction with an objective third-party professional evaluation designed to identify and inspire sound education and training practices.

Better Business Bureau

Better Business Bureau

A Training Division of ECPI University